It is more than a year since Model A was released. I was really confident in its quality, and the feedback I got from the customers was indeed great. The premium version of the Model A has been compared in many systems against the other amps, many of them being a current reference, and their owners always kept the Model A in their systems. Also, this feedback was a good basis for further work, and as mature and refined as it was, we looked at several details to improve upon it.

Consequently, several small changes came during this time, and the most visible one is in its bindings posts.

Firstly, a few things about the binding posts themselves. For me, the use of real copper was a must here, and Model A, since its release, had Audial’s made binding posts, machined of real copper. To make these binding posts we however had to go through the initial struggle with copper machining. We fully understood why real copper is not commonly used for this purpose, and why even manufacturers who avoid ubiquitous brass (typically 60/40 alloy of copper and zinc) and claim to make “copper connectors”, rather than real copper actually use “high copper” and similar alloys that still include a certain amount of zinc or similar elements. Such alloys make copper easier to process, and that is more important than improved rigidity, or savings in the material itself – real copper is tricky to work with.

The connectors themselves remained practically unchanged since Model A release. But there was also another major question we dealt here with, and it was how to protect these connectors from later corrosion. This question remained somewhat open during the year 2014.

Typically, corrosive materials protection is done by electroplating, and connectors you usually find in high end audio are gold plated. Gold, of course, does not corrode and it is a good conductor (not as good as copper and silver, though), however audiophiles are mostly not aware of what such a plating actually is. And it is usually only by a small part of real gold. If it were gold only, the required reliable layer would be too thick and expensive for production. Hence the layer of gold normally implies the use of an additional, “barrier” layer, typically made of nickel, so the gold can be only a tiny outer layer. Such a combination achieves good mechanical reliability and protection from corrosion, at a reasonable price. However the signal must pass through this additional layer of nickel, which conductivity is not good (for instance it is inferior to zinc conductivity), and even though such a solution may have its advantages in connectors carrying low level signals (such as RCA), here I have given up of it.

Instead, I settled on silver plating. Silver is in fact a better conductor than copper, and it is possible to apply up to 10 µm thick layer, required to reliably protect copper, at an acceptable price. Silver is also known for being prone to corrosion, however the product of its corrosion is mostly conductive, so it is acceptable in practical use.

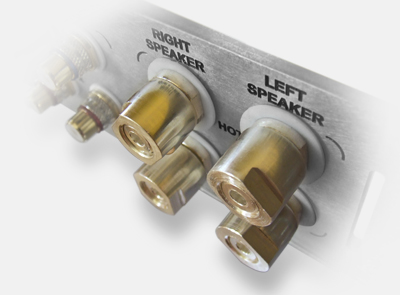

Fig. 1: Silver plated binding posts

(with washers made of Teflon, later replaced with polypropylene, for its better stiffness)

However, longer listening made me sure that the pure copper connectors, with no other elements outside, have a more smooth midrange, and overall more proper tone. Still, the problem with copper corrosion can be real, and after some time it may look very bad. The actual state will vary, according to actual copper content, handling, and atmospheric conditions, so everything may boil down to fingerprints that become visible, but then again the whole connector may acquire a certain layer of patina. And, as opposed to silver, the products of copper corrosion are less conductive. So we still looked for options to manufacture a pure copper connector that will be usable in the longer term.

The result is the binding posts mounted at Model A units produced since October 2014. They use copper electroplating, a technology that may look ineffective or redundant at first sight, however the outer layer of electrolytic copper does help corrosion resistance (and electric conductivity too), and in the regular home environment, they will work flawlessly for many years, without any special care or maintenance. And their sonic properties are unique, just as they are unique for being both machined of real copper, and copper electroplated.

Fig. 2: Copper plated copper binding posts at the back plate of the power amp version of the Model A